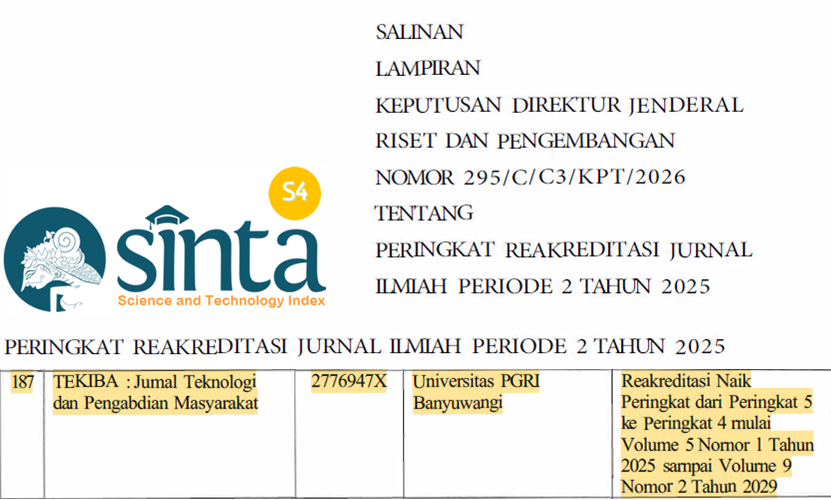

Sosialisasi dan Implementasi K3 Upaya Peningkatan Keselamatan Kerja di Alfamidi Cabang Pasuruan

DOI:

https://doi.org/10.36526/tekiba.v6i1.7114Keywords:

OHS, Safety Culture, Risk Control, Operational Efficiency, Retail IndustryAbstract

PT MIDI Utama Indonesia Tbk continues to face challenges in the implementation of Occupational Health and Safety (OHS/K3), including suboptimal employee understanding, uneven compliance with the use of personal protective equipment, and incomplete workplace safety supervision. This community service activity aims to enhance awareness, compliance, and implementation of OHS as an effort to control workplace accident risks and improve operational efficiency. The method applied was an implementative approach through socialization of work risk identification, OHS training, and the direct application of safety standards. The activity was conducted in the office and warehouse areas of Alfamidi Branch 2 Pasuruan, involving office employees, warehouse employees divided into two sessions according to the shift system, suppliers, as well as store managers and regional coordinators who participated online. The implementation involved company management, human resource practitioners, security personnel, and relevant institutions. Prior to the activity, understanding and compliance with OHS procedures were not evenly distributed, and the application of safety standards was not consistently implemented. Following the activity, there was an increase in awareness and compliance among all participants regarding OHS principles, operational activities became more orderly, and the potential for disruptions and workplace accident risks decreased.

References

[1] I. A. Wahyudi, N. F. Hidayat, M. R. Valentino, and M. R. Dwi, “Penerapan Pelaksanaan Keselamatan Dan Kesehatan Kerja (K3) Pada Karyawan,” EUNOIA: Jurnal Pengabdian Masyarakat, vol. 4, no. 2, pp. 65–70, Jul. 2025, doi: https://doi.org/10.36277/eunoia.v4i2.661

[2] L. Ummarah, D. Irwansyah, and B. Bakhtiar, “Analysis of Workplace Accident Risk Using the Hazard Identification Risk Assessment and Determining Control (HIRADC) Method in PMKS Pt. Sisirau,” PENA TEKNIK: Jurnal Ilmiah Ilmu-Ilmu Teknik, pp. 81–91, Nov. 2025, doi: https://doi.org/10.51557/hcyphv13

[3] D. C. Ningsih, I. K. Subagja, and A. Hakim, “Pengaruh Penerapan Kesehatan Keselamatan Kerja (K3) dan Produktivitas Kerja terhadap Kinerja Karyawan di PT. Artefak Arkindo (MK),” Jurnal Sosial Teknologi, vol. 4, no. 11, pp. 988–1000, Nov. 2024, doi: https://doi.org/10.59188/jurnalsostech.v4i11.27628

[4] Z. K. Fahmi, N. K. Nisa, N. Hidayati, and Mardiyah, “Strategi Rekrutmen untuk Meningkatkan Kepatuhan terhadap Standar K3,” Al-Marsus: Jurnal Manajemen Pendidikan Islam, vol. 2, no. 2, pp. 190–200, Dec. 2024, doi: https://doi.org/10.30983/al-marsus.v2i2.8645

[5] N. Lecia, A. Wijayati, and W. S. Widiarty, “Perlindungan Hukum Bagi Pekerja Yang Mengalami Kecelakaan Kerja Di Sektor Pertambangan,” Jurnal Sosial Teknologi, vol. 5, no. 9, pp. 3788–3801, Sep. 2025, doi: https://doi.org/10.59188/jurnalsostech.v5i9.32384

[6] Y. A. Nabila, N. Tanjung, S. Daulay, and A. Hasibuan, “Penerapan K3 (Keselamatan dan Kesehatan Kerja) Pada Karyawan Pabrik Kripik Tuntungan Dalam Upaya Mencegah Kecelakaan Kerja,” Quantum Wellness: Jurnal Ilmu Kesehatan, vol. 1, no. 2, pp. 122–131, May 2024, doi: https://doi.org/10.62383/quwell.v1i2.298

[7] K. T. Esterlita, L. Pontoh, T. Lubis, and R. Manuwus, “Penggunaan K3 di Proyek Konstruksi: Tantangan Dan Solusi Dalam Implementasi Yang Sering di Abaikan,” TEKNO, vol. 22, no. 89, pp. 1865–1871, Oct. 2024, doi: https://doi.org/10.35793/jts.v22i89.58523

[8] H. Abdurrahman, N. Rahdiana, A. A. W. Rahayu3, A. Suhara4, and M. F. Perdana, “Analisis Kesehatan Dan Keselamatan Kerja (K3) Dengan Metode Hirarc Pada Bidang Konstruksi: (Studi Kasus: Unit Operasi 2 PT. Wijaya Karya Beton),” Jurnal Teknologi dan Manajemen Industri Terapan, vol. 4, no. 3, pp. 908–919, Aug. 2025, doi: https://doi.org/10.55826/jtmit.v4i3.849

[9] R. Z. Amiroh, S. Sunarto, and S. Suryanto, “Pelaksanaan Strategi Komunikasi Keselamatan Kerja Pertambangan di PT XY,” Interaksi Online, vol. 13, no. 2, pp. 1231–1244, Mar. 2025, Accessed: Dec. 30, 2025. [Online]. Available: https://ejournal3.undip.ac.id/index.php/interaksi-online/article/view/50405

[10] Y. M. Rahayu, S. Suyato, and S. Setiawati, “Integrasi Pendidikan Kewarganegaraan Berbasis Nilai Moral dalam Meningkatkan Kesadaran K3 di Industri,” Jurnal Moral Kemasyarakatan, vol. 10, no. 2, pp. 818–832, Jul. 2025, doi: https://doi.org/10.21067/jmk.v10i2.11799

[11] S. Amirah, A. Sutikno, and J. Annovasho, “Pengenalan Keselamatan Kerja Di Laboratorium Melalui Kegiatan Pembuatan Poster Edukatif Pada Siswa Kelas X Man Kota Palangka Raya,” Bhakti Nagori (Jurnal Pengabdian kepada Masyarakat), vol. 5, no. 2, pp. 936–946, Dec. 2025, doi: https://doi.org/10.36378/bhakti_nagori.v5i2.5034

[12] S. Zahara, F. Gustiningsih, N. A. D. L. Putri, U. Hasanah, and A. A. A. Maududi, “Evaluasi Pelatihan Keselamatan terhadap Kesadaran K3 dan Tanggung Jawab Kerja Berdasarkan Etika Kerja Islam di Perusahaan Logistik,” AKSIOMA: Jurnal Sains Ekonomi dan Edukasi, vol. 2, no. 12, pp. 2643–2658, Dec. 2025, doi: https://doi.org/10.62335/aksioma.v2i12.2082

[13] I. K. Wiryajati, I. A. S. Adnyani, I. K. P. Putra, N. M. Seniari, and M. S. Yadnya, “Peran Sosialisasi Alat Pemadam Api Ringan (Apar) Dalam Membangun Budaya Keselamatan Di Lingkungan Kampus,” Jurnal Pepadu, vol. 6, no. 2, pp. 284–291, Jun. 2025, doi: https://doi.org/10.29303/pepadu.v6i2.5850

[14] M. A. Sasmitha, A. Andriyani, and T. Srisantyorini, “Pelatihan dan Pengawasan sebagai Upaya Meningkatkan Kepatuhan Penggunaan Alat Pelindung Diri (APD) untuk Menurunkan Tingkat Kecelakaan Kerja: Training and Supervision as an Effort to Improve Compliance with the Use of Personal Protective Equipment (PPE) to Reduce the Level of Workplace Accidents,” Buletin Kesehatan Mahasiswa, vol. 3, no. 3, pp. 157–171, May 2025, doi: https://doi.org/10.51888/jpmeo.v3i3.325

[15] T. A. H. Kandora et al., “Pengenalan Keselamatan dan Kesehatan Kerja (K3) bagi Siswa SMK Negeri 5 Pinrang: Evaluasi program edukasi berbasis simulasi,” Room of Civil Society Development, vol. 4, no. 4, pp. 647–658, Jul. 2025, doi: https://doi.org/10.59110/rcsd.677

[16] A. W. Kamilah and W. Bharata, “Program Kegiatan Safety Talk sebagai Penguatan Kesadaran Keselamatan Kerja pada PT. Eurotruk Transindo,” Jurnal Pengabdian Kepada Masyarakat (JPKM) TABIKPUN, vol. 6, no. 1, pp. 69–80, Mar. 2025, doi: 1 https://doi.org/0.23960/jpkmt.v6i1.208

[17] R. A. Firdaus, “Peran Karyawan dalam Budaya Keselamatan dan Kesehatan Kerja (K3) PT. Yura Putra Pratama,” Journal of Engineering and Applied Technology, vol. 1, no. 2, pp. 69–78, Nov. 2025, doi: https://doi.org/10.65310/c66s6610

[18] K. Imandiya, M. Zulkarnain, Novrikasari, and P. Noviadi, “Persepsi Pekerja dalam Budaya Keselamatan dan Kesehatan Kerja: Studi Kasus di Industri Berisiko Tinggi: Literature Review:” Media Publikasi Promosi Kesehatan Indonesia (MPPKI), vol. 7, no. 1, pp. 65–72, Jan. 2024, doi: https://doi.org/10.56338/mppki.v7i1.4287

[19] R. A. Praditya, R. Z. Prayuda, and A. Purwanto, “Penerapan Keselamatan dan Kesehatan Kerja (K3) dan Kepemimpinan Terhadap Kinerja Organisasi,” PROFESOR: Professional Education Studies and Operations Research, vol. 2, no. 02, pp. 1–9, Jun. 2025, doi: https://doi.org/10.7777/71marg43

[20] R. S. Dewangga and F. Lestari, “Hubungan Frontline Leadership Styles Terhadap Iklim Keselamatan Di Berbagai Industri,” Jurnal Cahaya Mandalika ISSN 2721-4796 (online), vol. 3, no. 2, pp. 927–939, 2022, doi: https://doi.org/10.36312/jcm.v3i2.2057

Downloads

Published

Issue

Section

License

Copyright (c) 2026 Hafidz Putra Perdana, Mentari Clara Dewanti

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.