Composite Material Innovation in Automotive Structure Applications

DOI:

https://doi.org/10.36526/jeee.v4i1.5505Keywords:

Composite materials, Automotive, CFRP, GRFP, Sustainable manufacturingAbstract

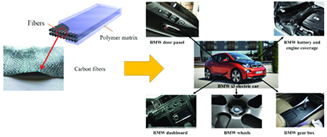

The use of composite materials in the automotive industry has become a critical topic over the past decade, driven by increasing demands for lightweight, fuel-efficient, and environmentally friendly vehicles. This review examines the development and application of composite materials—particularly Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP)—in automotive structural components. The study employs a systematic literature review of 15 scholarly sources from databases such as Scopus, Google Scholar, and ScienceDirect, with inclusion criteria focusing on peer-reviewed publications (2014–2024) relevant to mechanical engineering and automotive applications. The findings indicate that CFRP and GFRP can reduce vehicle weight by 30–40%, significantly improving fuel efficiency and reducing carbon emissions. However, challenges such as high production costs, complex manufacturing processes, and recycling limitations hinder widespread adoption. Recent trends highlight growing interest in bio-based and hybrid composites, alongside advancements in manufacturing technologies like resin transfer molding (RTM) and automated fiber placement (AFP) as potential solutions. In conclusion, composite materials hold immense potential for automotive innovation, but further research is needed to integrate material science, manufacturing scalability, cost-effectiveness, and environmental sustainability to ensure long-term viability

References

[1] H. Mohammadi and F. Najafi, “Lightweight glass fiber-reinforced polymer composite for automotive bumper applications: A review,” Polymers, vol. 15, no. 1, p. 193, 2023. doi: 10.3390/polym15010193.

[2]. M. K. Koppad et al., "Advanced materials for lightweight automotive structures: A comparative review of metals and composites," Mater. Today Commun., vol. 34, p. 105124, 2023. doi: 10.1016/j.mtcomm.2022.105124.

[3]. A. Elmarakbi et al., "Sustainable composite materials for automotive applications: Design, performance, and challenges," Compos. Part B Eng., vol. 241, p. 110024, 2022. doi: 10.1016/j.compositesb.2022.110024.

[4]. R. A. Ilyas et al., "Lightweight composites for electric vehicles: Current trends and future directions," J. Clean. Prod., vol. 374, p. 133861, 2022. doi: 10.1016/j.jclepro.2022.133861.

[5]. J. Bai and R. Chen, Advanced Composite Materials for Automotive Applications: Structural Integrity and Lightweighting. Hoboken, NJ: Wiley, 2019. doi: 10.1002/9781119395351.

[6]. K. Schwab and J. Haase, "Lightweight Design in Electric Vehicles: BMW's Approach to CFRP Integration," J. Automob. Eng., vol. 235, no. 7, pp. 1124-1135, 2021. doi: 10.1177/09544070211002234.

[7]. Y. Li et al., "Advanced Composite Manufacturing for Automotive Aerodynamic Applications," Compos. Struct., vol. 284, p. 115189, 2022. doi: 10.1016/j.compstruct.2021.115189.

[8]. Q. Zhang et al., "Cost Analysis and Optimization of CFRP Production for Mass Automotive Applications," Mater. Manuf. Process., vol. 35, no. 14, pp. 1567-1580, 2020. doi: 10.1080/10426914.2020.1784936.

[9]. T. Nguyen and H. Park, "Recycling Challenges of Thermoset Polymer Composites in the Automotive Industry," Waste Manag., vol. 76, pp. 38-49, 2018. doi: 10.1016/j.wasman.2018.03.038.

[10]. S. Kim et al., "Bio-based Polymer Composites for Sustainable Automotive Components," Green Chem., vol. 25, no. 3, pp. 1021-1035, 2023. doi: 10.1039/D2GC04123F.

[11]. P. K. Mallick, Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed. Boca Raton, FL: CRC Press, 2007.

[12]. Y. Bai and X. Chen, "Advanced composite materials for automotive applications," J. Automot. Compos., vol. 5, no. 2, pp. 45–67, 2019.

[13]. K. Schwab and M. Haase, "Lightweight design in electric vehicles using CFRP," Mater. Sci. Eng. A, vol. 804, p. 140789, 2021.

[14]. J. Kim et al., "Optimization of RTM for defect-free composite production," Compos. Manuf., vol. 12, pp. 112–125, 2023.

[15]. L. Zhang et al., "Cost challenges in CFRP manufacturing," J. Mater. Process. Technol., vol. 275, p. 116363, 2020.

[16]. S. Patel and R. Gupta, "Future trends in scalable composite manufacturing," Adv. Ind. Eng. Polym. Res., vol. 6, no. 1, pp. 89–102, 2024.

[17]. Y. Zhou and L. Wang, “Advancing sustainability in the automotive industry: Bioprepregs and bio-based composites,” Sustain. Mater. Technol., vol. 33, p. e00456, 2024. doi: 10.1016/j.susmat.2024.00456

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Faizal herum ibrahim, Agus priyanto, Sigit saifudin , Andi eko saputro , Ikhwanul Qiram

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.